We believe in growth through innovation and sustainability and acting responsibly

Our exceptional product quality is equally matched with our excellence in problem solving capabilities and technical customer service with an extensive operational network.

Discover MoreWe believe in growth through innovation and sustainability and acting responsibly

Paints & Coatings

Ceramics

Printing Ink

Textiles

Rubber

Construction

Water Treatment

Plastics & Polymer

Agriculture

Our Values

They guide the way we work with our business partners, within our communities and with each other. Through integrity, accountability, passion, humility, simplicity, safety and a focus on success, we have created a vibrant company culture where ideas can blossom, people can thrive and success can flourish.

Our Commitment

Our brand promise, our deep enrooted commitment to building a robust, sustainable and responsible business for the long run. Delivering performance for our shareholders, remaining innovative for our customers, building lasting relationships for our employees, partners and communities.

Our Credibility

Collabarative by nature and easy to do business with, we are responsive with honesty and integrity with a hands on approach.

20 Microns – leading manufacturer and supplier of industrial minerals and speciality chemicals in India, aligns it’s research and innovation portfolio, being an integral part of it’s core strategy and is key to continued growth. We design new processes, technologies and products, with our continuous innovative approach by understanding our customers requirements and meeting their expectations by working with them on new innovative products.

20 Microns is well equipped with the most advanced quality control instruments to produce industrial minerals, paint additives, quartz, fillers for paint and ceramics etc. of highest standard of quality and consistency by it’s well trained and experienced Chemists, Geologists and Engineers who undertake continuous product upgradation and improvement and maintain consistency in quality.

Waghodia (Vadodara)

Vadadala (Vadodara)

Vadodara

Mumbai

Mumbai

Kolkata

Chennai

Delhi

Bhuj

Haldwani

Haldwani

Alwar

Hosur

Udaipur

Swaroopgunj

Tirunelveli

Anantpur

Makrana

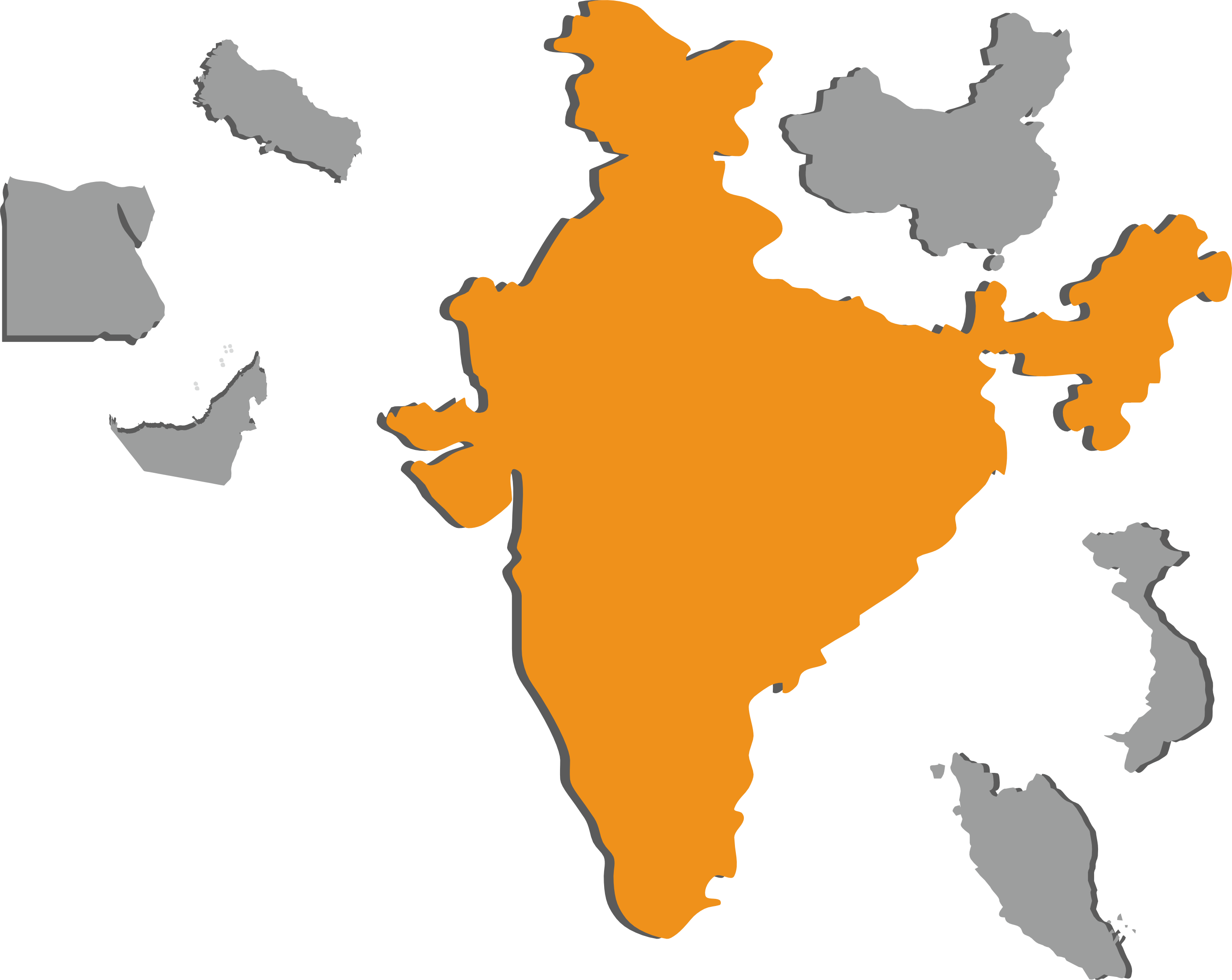

Malaysia

Vietnam

Egypt

Turkey

Mundra

China

Our Network

20 Microns is constantly endeavouring in expanding its domestic as well as global footprints in order to tap the potential resources for catering future opportunities around the world. We are successful in creating the largest infrastructure network for Industrial Minerals and Speciality Chemicals in India by covering every part of the country and our experienced exploration and project team is always on the hunt for expanding our network and be approachable by all our customers.

Head Quarter

Head Quarter Corporate Office

Corporate Office Manufacturing Units

Manufacturing Units Office / Warehouse

Office / Warehouse Sourcing Point

Sourcing PointLet's get in touch and explore business opportunities

Connect With Us