Barytes, also known as barium sulfate (BaSO₄), is a naturally occurring inorganic mineral and the primary ore of barium. It is a white, opaque powder with high specific gravity (about 4.5 g/cm³). These key properties, especially density and chemical inertness, make barytes a preferred filler and extender pigment in industrial formulations.

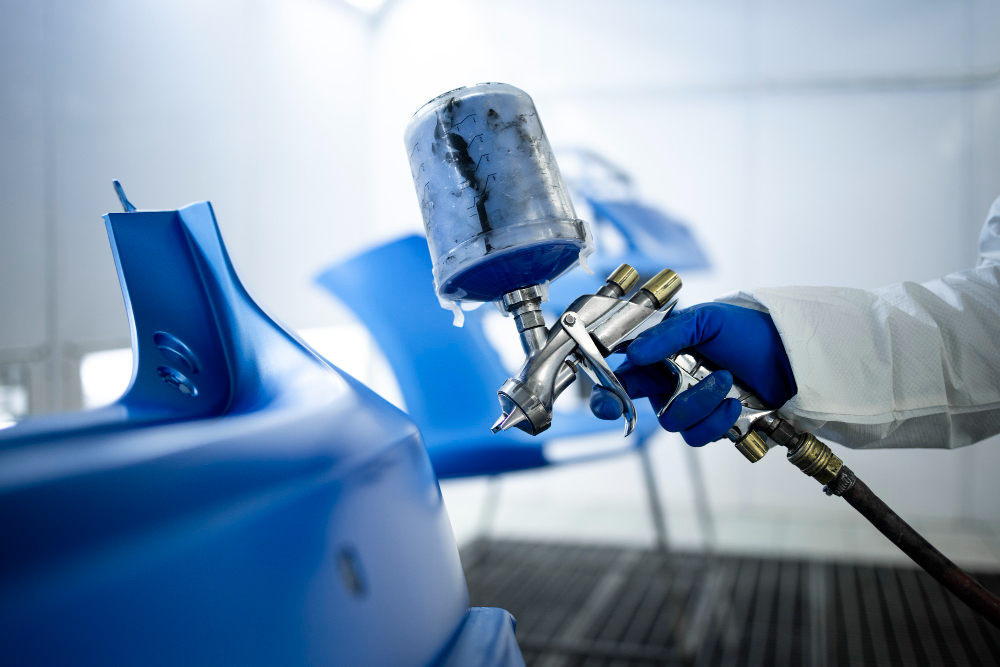

Widely used in paints and coatings, barytes reduces the need for expensive pigments like titanium dioxide and lowers material cost. Its Mohs hardness (3.0–3.5) lends durability and scratch resistance to end products.

Paints & coatings: Improves dispersion, flow, leveling, and gloss; enhances powder coating durability.

Plastics & polymers: Adds stiffness and stability, lowers shrinkage and costs.

Oil & gas: Serves as a high-density weighting agent in drilling muds for pressure control and well stabilization.

Medical imaging: High-purity grade used as an X-ray contrast agent for gastrointestinal scans.

Rubber & automotive: Hard filler for rubber products, brake pads, and plastic parts; boosts rigidity, heat resistance, and vibration damping.

With decades of mineral processing expertise, we supply consistent, high-purity barytes tailored to your industrial specification. Our rigorous chemical and physical quality control at every production stage meets demanding industry standards. Choose from multiple grades and tailored particle sizes, with flexible packaging and reliable global delivery. Our technical support helps you optimize cost and performance for your application.

Q: What is Barytes (Barium Sulfate)?

A: Barytes (BaSO₄) is a white, high-density, non-toxic mineral, valued as a durable filler and extender due to its chemical stability and moderate hardness.

Q: What are the main uses of Barytes?

A: It is used as a filler in paints, coatings, plastics, rubber, ceramics, and paper. The primary application is as a high-density weighting agent in oil and gas drilling fluids. It is also found in automotive components and medical imaging.

Q: What grades of Barytes do you offer?

A: We offer Baryte Chips, Micron Baryte, Grey Baryte, Barigloss, Micro Basofix, and Basofix—ranging from coarse chips to ultrafine precipitated powders for everything from drilling muds to premium coatings.

Q: How does Barytes enhance paints and coatings?

A: It increases film thickness, improves gloss and smoothness, strengthens durability, and partially replaces TiO₂ without sacrificing stability. It also boosts gloss retention and hardness.

Q: Can barytes help reduce VOCs and costs?

A: Yes. Its low oil absorption and ability to replace costly pigments allow higher filler loads, reducing binder and solvent requirements—resulting in lower VOCs and overall costs.

Applications

Let's get in touch and explore business opportunities

Connect With Us